Overcoming the formwork challenges in modern architecture

Overcoming the formwork challenges in modern architecture

In the fast-paced construction industry, formwork is the cornerstone of creating robust and precise structures, but it also often faces numerous challenges, such as material aging and alignment issues, which can lead to project delays and increased costs. Whether it's temporary formwork for concrete pouring or reusable formwork in industrial production, substandard formwork can result in structural defects and safety hazards. This article will explore these common problems and provide practical solutions, highlighting innovative products such as high-strength formwork to simplify your construction process.

Understanding the core issues of traditional templates

One of the main problems with traditional formwork is its susceptibility to wear, especially in harsh environments such as dampness, chemicals, and heavy loads, where the wear rate is accelerated. Workers often encounter difficulties during assembly and disassembly, leading to time-consuming adjustments and increased labor costs. Furthermore, misalignment during installation can result in uneven concrete surfaces, affecting the integrity of the final structure. For outdoor applications, formwork must withstand various weather conditions without deformation, a requirement that traditional materials often fail to meet, leading to costly replacements and project delays.

Mature Solution: Introducing Innovative High-Strength Template Technology

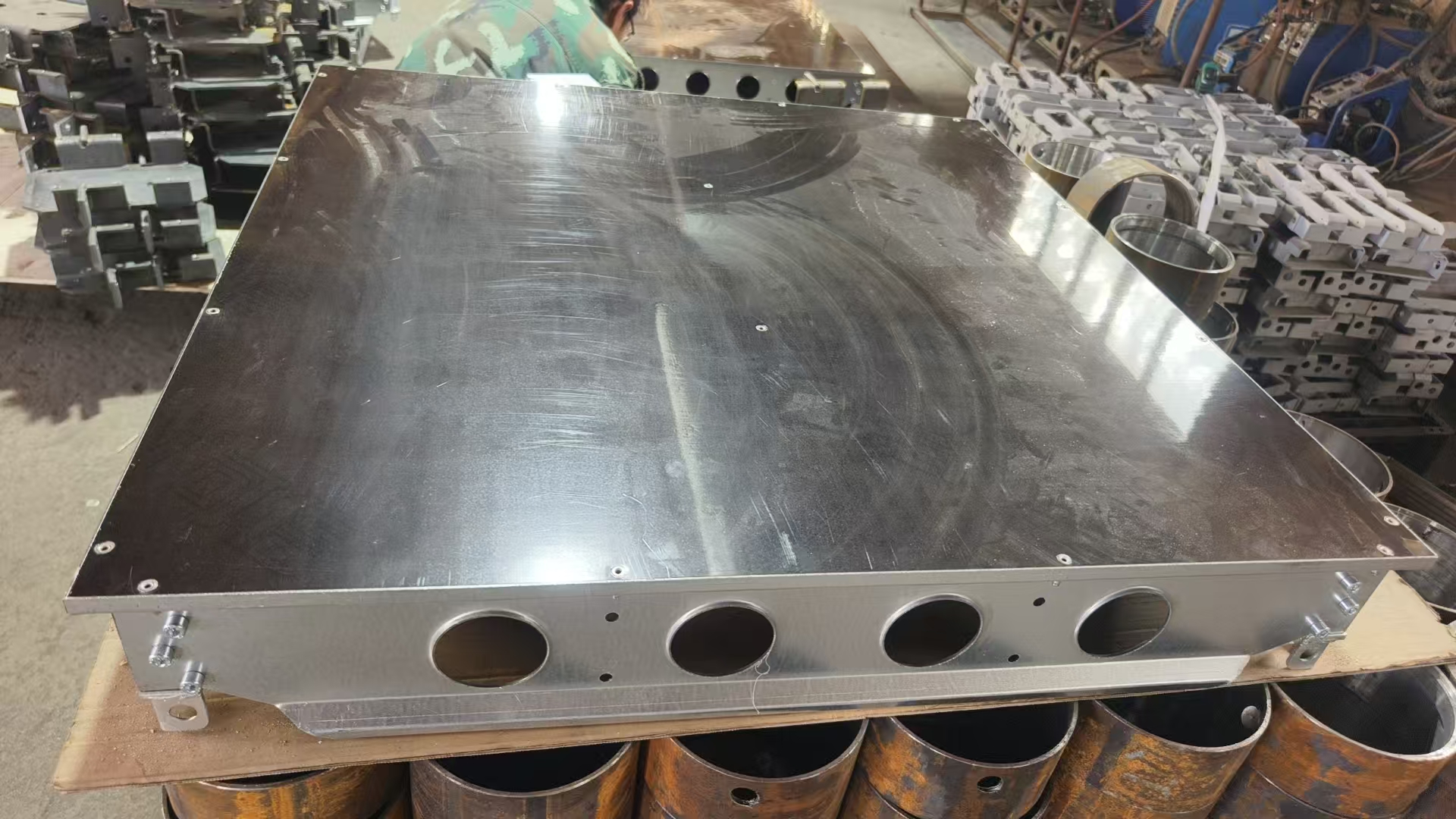

To address these challenges, advanced solutions such as high-strength formwork have emerged, revolutionizing the field of formwork applications. This multi-functional component, precision-engineered for superior durability and abrasion resistance, is ideal for demanding industrial and construction projects. Its smooth, polished surface minimizes friction, ensuring smooth operation during use; carefully designed circular openings facilitate efficient handling and secure integration with other components. Using this high-strength formwork, construction teams can reduce assembly time by up to 30%, minimize material waste, and achieve superior structural performance, directly addressing the durability and alignment issues inherent in traditional methods.

Enhance outdoor safety and durability with specialized panels

For projects extending into outdoor environments, formwork must also function as a protective barrier, and our advanced outdoor safety panels offer a reliable solution. Designed with both functionality and aesthetics in mind, the panel's smooth surface resists environmental damage while maintaining a modern look. Secured with evenly spaced, high-quality screws, the panel ensures maximum stability and prevents displacement issues common with exposed formwork. This integration not only protects equipment and structures but also enhances visual appeal, solving the dual challenges of safety hazards and unsightly appearance in outdoor construction. Its weather resistance extends the lifespan of formwork installations, reduces maintenance needs, and allows for seamless integration with various safety systems.

Implement best practices in formwork construction for long-term success

Beyond product selection, formwork optimization involves strategic planning, such as regular inspections and proper storage to prevent premature damage. Combining high-strength formwork with outdoor safety panels creates a comprehensive system that balances indoor precision with outdoor durability. Construction teams report fewer errors and faster project completion rates, resulting in significant cost savings, after using these solutions. By focusing on high-quality engineered formwork, you can turn potential defects into opportunities for increased efficiency and excellence, ensuring your projects stand the test of time.

In short, solving the formwork challenge requires a shift towards innovative technologies that are durable, easy to use, and balance strength and adaptability. With tools such as high-strength formwork and outdoor safety panels, construction professionals can break through traditional limitations to create projects that are not only fully functional but also aesthetically pleasing and safe.

Recycling saves costs